How to Choose a 5 Ton Portable Gantry Crane Safely for Floors

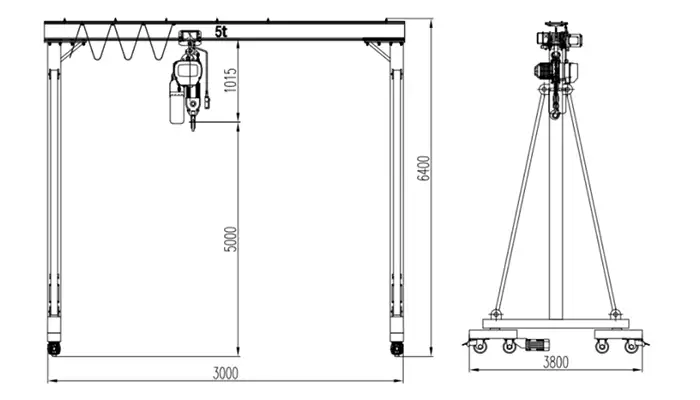

Choosing the right 5 ton portable gantry crane is more than just picking a crane that can lift your load. It's also about protecting the floor underneath. Not all floors in workshops or small industrial plants are designed to handle heavy concentrated weights. If the crane's wheels are too small, or if the load is unevenly distributed, the floor can crack, chip, or even fail. And trust me, repairing a damaged concrete floor isn't cheap—or quick. Even if your floor looks strong, repeated crane movement can cause hidden stress over time. This means small cracks or dents might appear after just a few months of use. For buyers, understanding how wheel load interacts with floor capacity is just as important as knowing the crane's lifting weight. Choosing the right 5 ton gantry crane is more than just picking a crane that can lift your load. It's also about protecting the floor underneath. Not all floors in workshops or small industrial plants are designed to handle heavy concentrated weights. If the crane's wheels are too small, or if the load is unevenly distributed, the floor can crack, chip, or even fail. And trust me, repairing a damaged concrete floor isn't cheap—or quick. Even if your floor looks strong, repeated crane movement can cause hidden stress over time. This means small cracks or dents might appear after just a few months of use. For buyers, understanding how wheel load interacts with floor capacity is just as important as knowing the crane's lifting weight. 5 ton portable gantry cranes are popular in workshops, maintenance shops, small factories, and light industrial facilities. These cranes are valued for their mobility and ease of use, especially when rail-mounted overhead cranes aren't an option. However, many of these settings were not built with heavy mobile equipment in mind. Floors may be: In these environments, even a crane that only lifts 5 tons can put significant pressure on a small section of floor, especially if the weight is concentrated on a few wheels. A lot of buyers focus only on lifting capacity and assume "if the crane can lift it, it's fine." That's not true. The real risk is the floor load per wheel. Floor damage can take several forms: These problems don't just cost money in repairs—they can delay production, compromise safety, and reduce the crane's usable lifespan. A careful assessment of both crane design and floor bearing capacity saves time, money, and headaches in the long run. Floor bearing capacity is simply the maximum weight a floor can safely hold over a specific area without sustaining damage. Think of it as the floor's strength limit. When you place a heavy crane or load in one spot, the floor has to spread that weight safely. If it can't, you risk cracks, dents, or even more serious structural problems. For a 5 ton portable gantry crane, understanding this number is critical. It's not just the crane's total weight that matters—it's how that weight is distributed across each wheel. A small crane on a weak floor can cause more damage than a heavier crane on a reinforced surface. Several practical factors determine how much weight your floor can safely handle: You don't have to guess your floor's capacity. There are practical ways to verify it: Be cautious if your floor shows any of the following signs: If you notice any of these issues, it's worth reinforcing the floor or choosing a crane design that reduces wheel load before placing a heavy gantry crane on it. Wheel load is the amount of weight that rests on each individual wheel of your gantry crane. It's not the total weight of the crane, but how that weight is spread across its wheels. For a 5 ton portable gantry crane, the wheels bear both the crane's own weight and the weight of the load being lifted. If a crane has only four wheels, each wheel carries a higher portion of the total weight than an eight-wheel design. That means the same crane can be far gentler on the floor if it has more wheels, or if the wheels are wider or made from softer materials. Even a floor that looks strong can fail if the wheel load is too high. Here's what can happen: In short, wheel load is a major factor in floor safety. Ignoring it can turn a simple lifting operation into a costly repair job. Several key factors determine how much load each wheel carries: Number of Wheels Wheel Material and Size Crane Span and Lifting Height To protect your floor, it's useful to calculate approximate wheel loads before buying or operating a crane. A simple formula is: Wheel load = (Total crane weight + maximum load) ÷ number of wheels For example, a 5 ton crane weighing 2 tons lifting a 5 ton load with four wheels: Safety margin: It's wise to add 20–30% extra for dynamic effects like acceleration, braking, or uneven floors. This means planning for 2.1–2.3 tons per wheel rather than 1.75. By calculating wheel loads, you can: When dealing with sensitive or older floors, the way a crane's weight is spread across its wheels makes a big difference. The material of your crane's wheels directly affects floor safety: Flexibility in design can help protect floors in tricky environments: It's tempting to buy a crane with higher capacity "just in case," but this can be counterproductive on sensitive floors: By combining wheel configuration, floor-friendly materials, modular design, and appropriate capacity, buyers can safely operate a 5 ton gantry crane on sensitive or older floors without damaging the surface. Even the best crane design can't fully prevent floor damage if proper protection isn't in place. Simple precautions can save significant repair costs: How you operate the crane has a direct impact on floor safety: Ongoing monitoring of your floor ensures early detection of potential problems: Choosing a 5 ton portable gantry crane isn't just about lifting capacity—it's about protecting your floors and keeping operations safe. Here are some practical tips to help buyers make the right choice: More wheels mean the crane's weight is spread across a larger area, reducing pressure on the floor. For sensitive or older floors, consider: Even small changes in wheel design can prevent long-term damage and reduce maintenance costs for your workshop floor. Don't assume that a crane can go anywhere just because it lifts your load. Consider the floor bearing capacity when selecting your crane. Practical steps include: Matching crane type to the floor ensures long-term safety and prevents hidden damage that may appear months later. If you're doing short-term projects on older or delicate floors, renting or using modular gantries can be safer and more cost-effective: This approach reduces risk and allows flexibility for different floor types. Every floor is unique, and sometimes off-the-shelf cranes aren't enough. Talking to the manufacturer can help you: Manufacturer guidance ensures your crane works safely and efficiently without damaging the floor, saving you repair costs and downtime.Introduction

Purpose: Why Floor Safety Matters When Choosing a Gantry Crane

Where 5 Ton Portable Gantry Cranes Are Used

Buyer Pain Point: The Hidden Costs of Floor Damage

Understanding Floor Bearing Capacity

Definition: What Floor Bearing Capacity Means

Factors Affecting Floor Capacity

How to Check Your Floor Before Buying

Red Flags That Your Floor May Not Be Ready

Wheel Load Distribution

What is Wheel Load?

Why Wheel Load Matters

Factors That Influence Wheel Load

Calculating Safe Wheel Load

Gantry Crane Design Considerations for Sensitive Floors

Choosing the Right Wheel Configuration

Use of Floor-Friendly Wheels

Adjustable or Modular Gantries

Lifting Capacity vs. Floor Safety

Installation and Operational Best Practices

Floor Protection Measures

Movement Strategies

Regular Floor Inspections

Practical Tips for Buyers

Prioritize Crane Designs with Multiple Wheels

Match Crane Type to Actual Floor Capacity

Consider Rental or Modular Cranes for Temporary Work

Consult with Manufacturers for Custom Solutions

Conclusion

When selecting a 5 ton portable gantry crane, it’s easy to focus only on lifting capacity. But floor safety is just as important. A crane that is too heavy, poorly designed, or fitted with the wrong wheels can cause cracks, dents, or structural damage—costly problems that can disrupt your workshop operations.

Choosing the right gantry crane isn’t just about lifting your load—it’s about protecting your floors, maintaining safety, and ensuring long-term efficiency. For most buyers, an 8-wheel, floor-friendly gantry crane offers the best balance. It spreads the weight across more points, reduces pressure on delicate floors, and allows smoother movement while still handling the required lifting tasks.

By considering wheel configuration, floor-friendly materials, modular design, and actual floor capacity, you can prevent damage, reduce maintenance costs, and operate your crane safely for years to come. A well-chosen gantry crane keeps both your loads and your floors safe, giving you peace of mind every time you lift.